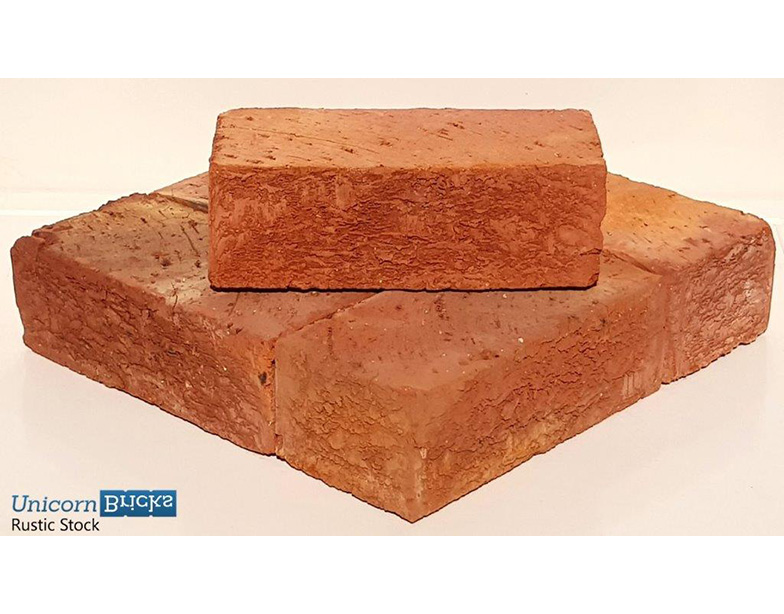

Clay Stock Brick (rustic)

Clay Stock Brick (rustic)

NFP/NFX (non face plaster/ non face extra)

Specifications:

Weight: 2.8 kg

Dimension: 220mm x 100mm x 70mm

Average Strength: +- 23MPa

Quantity per pallet: 500

The properties and benefits of clay bricks

- Low maintenance, Clay bricks saves time and money by requiring little to no maintenance.

- Have a low carbon footprint thereby benefiting the environment. Due the minimal (if any) maintenance required, carbon debt is misused because of the reduced need of painting or replacement.

- Fire resistant. Clay bricks are incombustible. This means they cannot start – or contribute to – a fire. They can also resist high levels of heat without damage due to the fact that they are fired at temperatures of between 1000°C and 1200°C

- Easy finish, no extra work is required once bricks are set.

- The compressive strength of clay bricks allows it to be successfully used in the building of multi-storey structures.

- Clay bricks have excellent structural integrity and a high load-bearing capacity. Clay bricks have a compressive strength from 7MPa all the way to 50MPa.

- Cost effective as a result of the overall benefits of clay brick.

- Clay bricks provides cost efficiencies in a variety of ways. The consistent sizes allow for easy building, and the modular shape means they can be transported easily. Being weatherproof, clay bricks can be stored on site and do not require special storage facilities.

A VISIT TO THE BRICK-YARD

Parts of the Brick Making Process

The popularity of clay bricks

Throughout the country the popularity of clay bricks is on the increase. From Rustenburg to Cape Town and everywhere in between the benefits of clay bricks have been felt.

These benfits, both instant and long term, have been what has swayed a large number of first time builders to make clay bricks their building material of choice.

It can get very hot in certain parts of South Africa and the thermal properties of clay bricks allows the building to remain cool. The opposite happens in areas where the temperature can dip rather low.

The thermal properties of the clay brick and intelligent design will allow heat to be absorbed when the sun shines and for the bricks to release the heat slowly as the ambient temperature begins to dip.

Harnessing the properties of the elements, clay bricks can be formed and fired so that they deliver on strength, longevity and appearance. The versatility of clay bricks is of such a nature that they can be used both inside and outside and unless it's a clay stock brick there are savings that can be had, due to the brick not requiring plaster or paint.

Clay stock bricks have the same qualities as clay facebricks except that they are usually applied to an inner wall which will eventually be plastered and painted.

The Cost of bricks

Without having bricks, the building process will undoubtedly halt or return to a time where sticks and skins were used to create places that would keep the elements out.

When selecting a brick for building, the type of structure you are building is a key factor, especially when it comes to cost. As a cost effective measure, buildings are generally not intended for the short term. If needs change, buildings are rather repurposed than rebuilt. Permanent structures are intended to last indefinitely and as a result you would want to choose a brick which will add to the quality of the build.

Clay bricks deliver both cost efficiency in the initial build as well as in the long term. The cost of clay bricks can be measured against the finish of the building; clay face bricks do not require plastering or paint finishes and as such carry a saving. Thermal properties of clay bricks will also lend themselves to savings on heating and cooling, thus also helping to reduce the carbon footprint of the build.

Keep it local

Clay bricks will offer the most effective and practical solution to your building requirements with short and long term savings. To further reduce the cost of the build consider buying your clay bricks from a local supplier, this will reduce or possibly eliminate the transport costs while helping to stimulate the economy in your area.

Making And Firing OF Clay BrICKS

Parts of the Brick Making Process

Types of clay bricks

Face bricks

These bricks are designed in such a way that added to their inherent qualities of strength and durability, face bricks can be used to finish off the design of a structure without being plastered and painted.

The colour of a brick is mostly determined by the firing technique that is used but the chemical content of the clay will also determine certain of the characteristics that can be seen and add to the overall look of a building.

Stock Bricks

These are the stalwarts of building with clay bricks. Inner walls and in many cases also outer walls are built with these bricks because they lend themselves well to plastering and then to a coat of paint to give the building its final appearance. Clay stock bricks do not have to be plastered however the finish is not always uniform and this is why they get allocated the position behind the plaster and paint.

Clay Maxi Bricks

As with other maxi bricks, the clay maxi brick is substantially larger than ordinary bricks. Fewer of these are used for building projects than standard size bricks.

The bricks are the same height as standard clay bricks but do have increased length and width which means fewer bricks used, and a thicker wall, leading to improved thermal insulation.

The benefits of clay brick will remain for as long as the bricks are maintained and your building stands. There are some things to consider when building and some maintenance requirements that may impact on the longevity of the bricks and the buildings.